TIN TỨC

12.04.21

Euroklimat chillers and the production of anti-COVID 19 vaccines

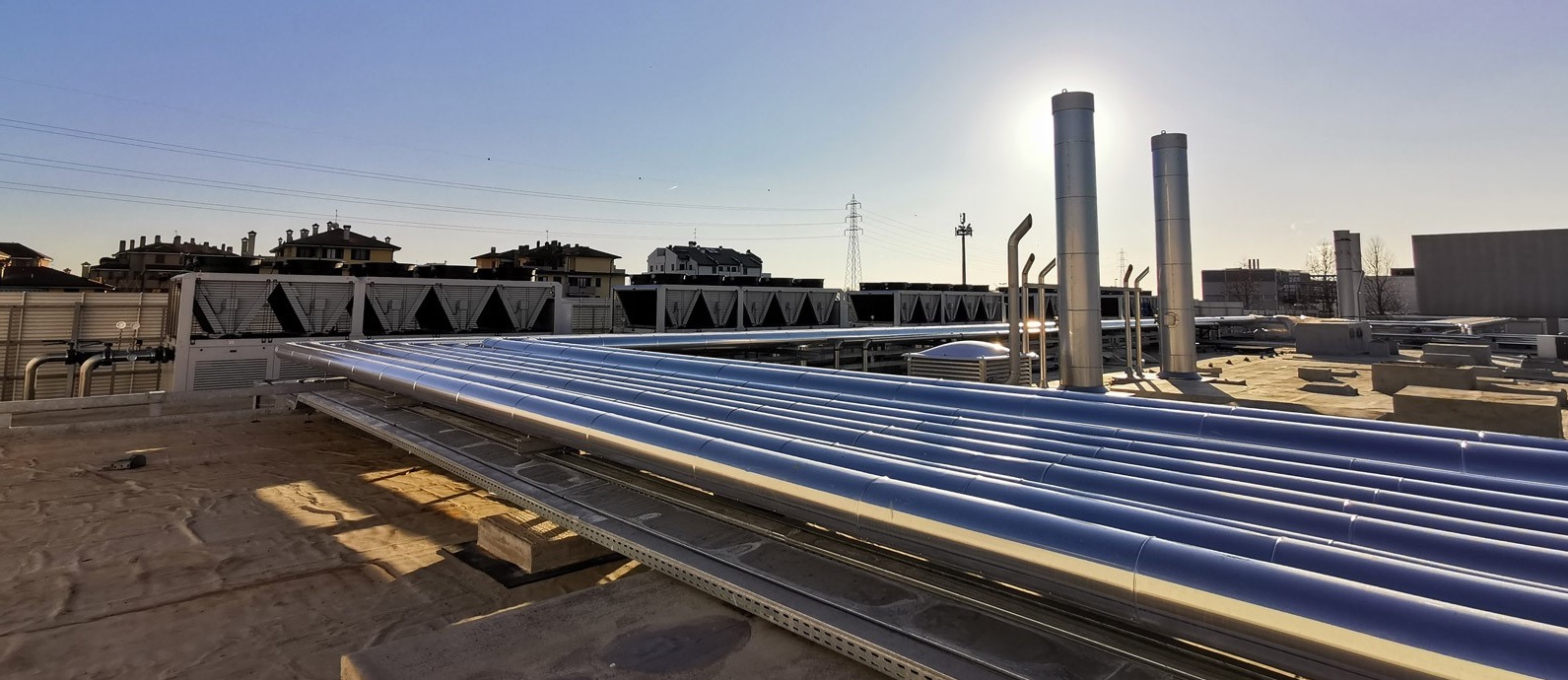

Last week, a great news arrived: our important customer near Monza has signed the first agreement to produce 10 million doses of the Sputnik V vaccine in Italy by 2021.

The pharmaceutical plant uses a total of 5 Euroklimat high-efficiency air-cooled chillers with Super Low Noise sound emissions and double electric pump: 3 EKS HE A PS/SL/AS/EC/OO 180-6-2 and 2 EKS HE A PS/SL/AS/EC/OO 110-4-2, units designed to reach lowest energy consumption and highest efficiency.

These chillers are characterized by scroll compressors with R410A refrigerant, Shell & Tube evaporators, microchannel condensers and EC silenced fans with bionic blades.

Each EKS HE A PS/SL/AS/EC/OO 180-6-2 has a cooling capacity of 510 kW and each EKS HE A PS/SL/AS/EC/OO 110-4-2 has a cooling capacity of 315 kW (with an outdoor temperature of 35 °C and with evaporator water temperature IN/OUT = 12/7 °C).

The 5 units are managed by a cascade system in order to produce the right quantity of chilled water in function of the required cooling load imposed by the pharmaceutical industrial process. The master unit communicates with the slave units via an Ethernet network in ModBus® protocol.

12.04.21

Euroklimat chillers and the production of anti-COVID 19 vaccines

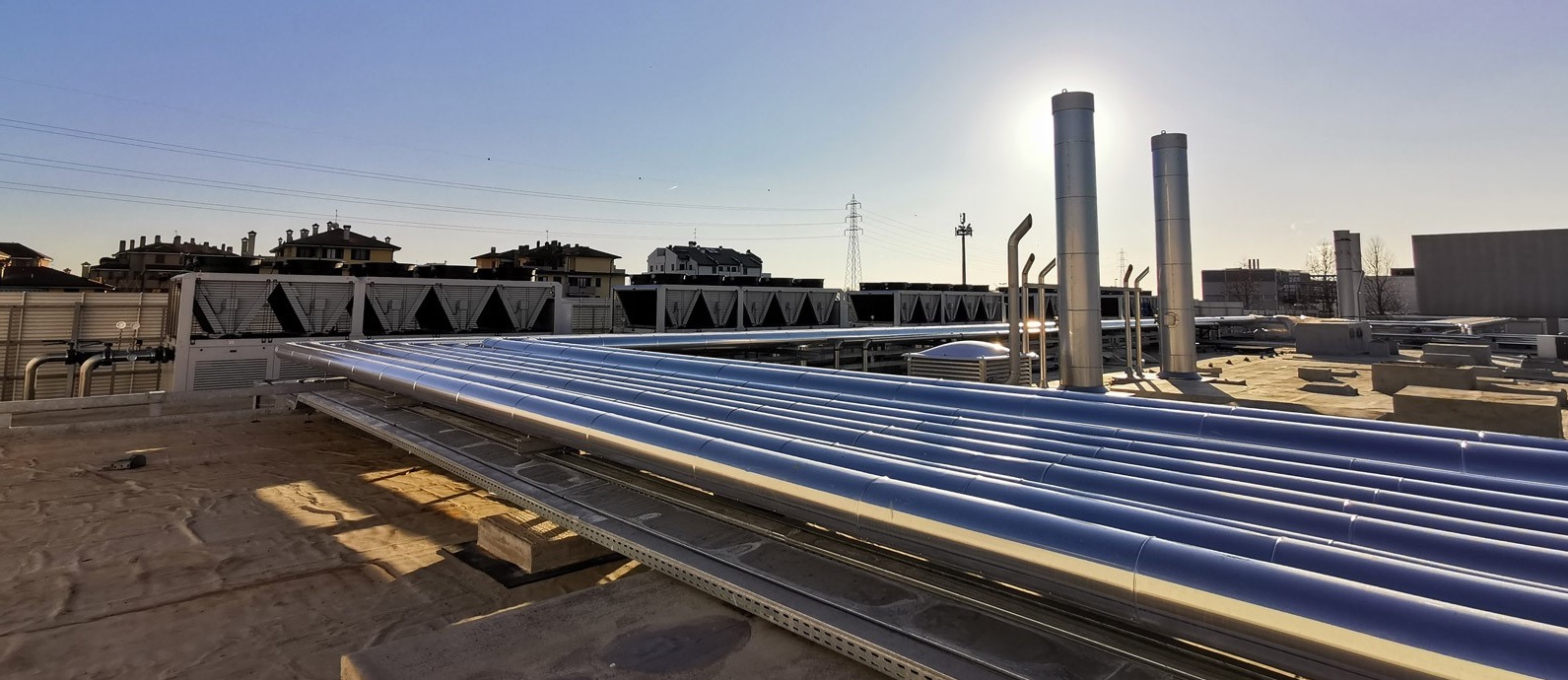

Last week, a great news arrived: our important customer near Monza has signed the first agreement to produce 10 million doses of the Sputnik V vaccine in Italy by 2021.

The pharmaceutical plant uses a total of 5 Euroklimat high-efficiency air-cooled chillers with Super Low Noise sound emissions and double electric pump: 3 EKS HE A PS/SL/AS/EC/OO 180-6-2 and 2 EKS HE A PS/SL/AS/EC/OO 110-4-2, units designed to reach lowest energy consumption and highest efficiency.

These chillers are characterized by scroll compressors with R410A refrigerant, Shell & Tube evaporators, microchannel condensers and EC silenced fans with bionic blades.

Each EKS HE A PS/SL/AS/EC/OO 180-6-2 has a cooling capacity of 510 kW and each EKS HE A PS/SL/AS/EC/OO 110-4-2 has a cooling capacity of 315 kW (with an outdoor temperature of 35 °C and with evaporator water temperature IN/OUT = 12/7 °C).

The 5 units are managed by a cascade system in order to produce the right quantity of chilled water in function of the required cooling load imposed by the pharmaceutical industrial process. The master unit communicates with the slave units via an Ethernet network in ModBus® protocol.

12.04.21

Euroklimat chillers and the production of anti-COVID 19 vaccines

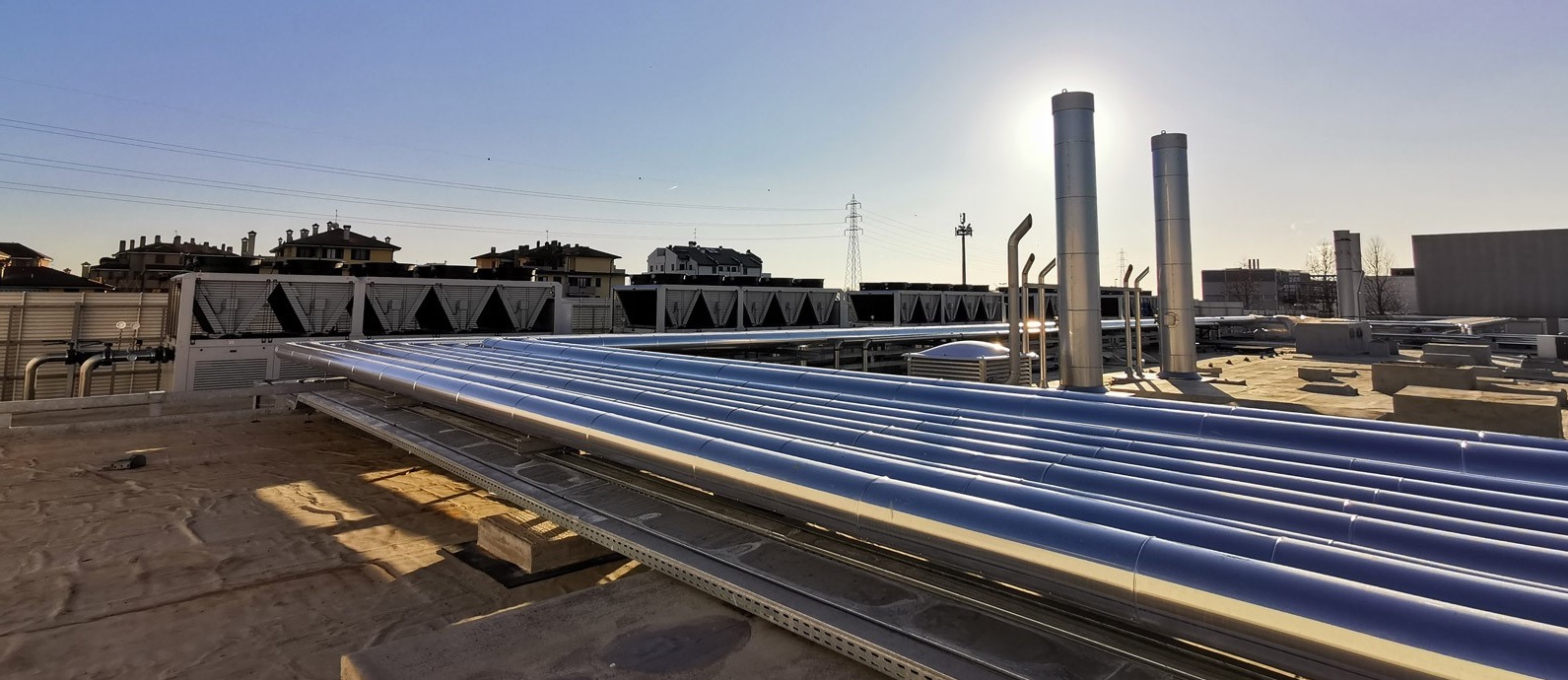

Last week, a great news arrived: our important customer near Monza has signed the first agreement to produce 10 million doses of the Sputnik V vaccine in Italy by 2021.

The pharmaceutical plant uses a total of 5 Euroklimat high-efficiency air-cooled chillers with Super Low Noise sound emissions and double electric pump: 3 EKS HE A PS/SL/AS/EC/OO 180-6-2 and 2 EKS HE A PS/SL/AS/EC/OO 110-4-2, units designed to reach lowest energy consumption and highest efficiency.

These chillers are characterized by scroll compressors with R410A refrigerant, Shell & Tube evaporators, microchannel condensers and EC silenced fans with bionic blades.

Each EKS HE A PS/SL/AS/EC/OO 180-6-2 has a cooling capacity of 510 kW and each EKS HE A PS/SL/AS/EC/OO 110-4-2 has a cooling capacity of 315 kW (with an outdoor temperature of 35 °C and with evaporator water temperature IN/OUT = 12/7 °C).

The 5 units are managed by a cascade system in order to produce the right quantity of chilled water in function of the required cooling load imposed by the pharmaceutical industrial process. The master unit communicates with the slave units via an Ethernet network in ModBus® protocol.